In car part production hemming is used in assembly as a secondary operation after deep drawing trimming and flanging operations to join two sheet metal parts outer and inner together.

Hemming operation in sheet metal.

In this process usually a sheet is bent with the help of inner sheet in three different stages.

Hems do more than just eliminate sharp edges.

The two newly formed layers then lie flush with each other.

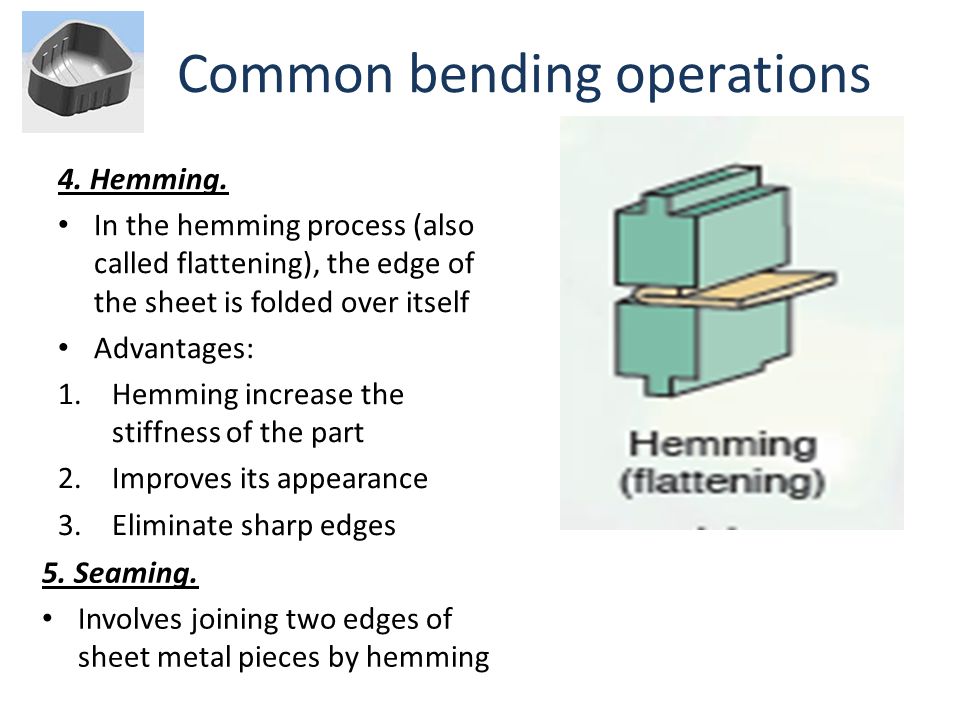

Hemming is the process in which the edge is rolled flush to itself while a seam joins the edges of two materials.

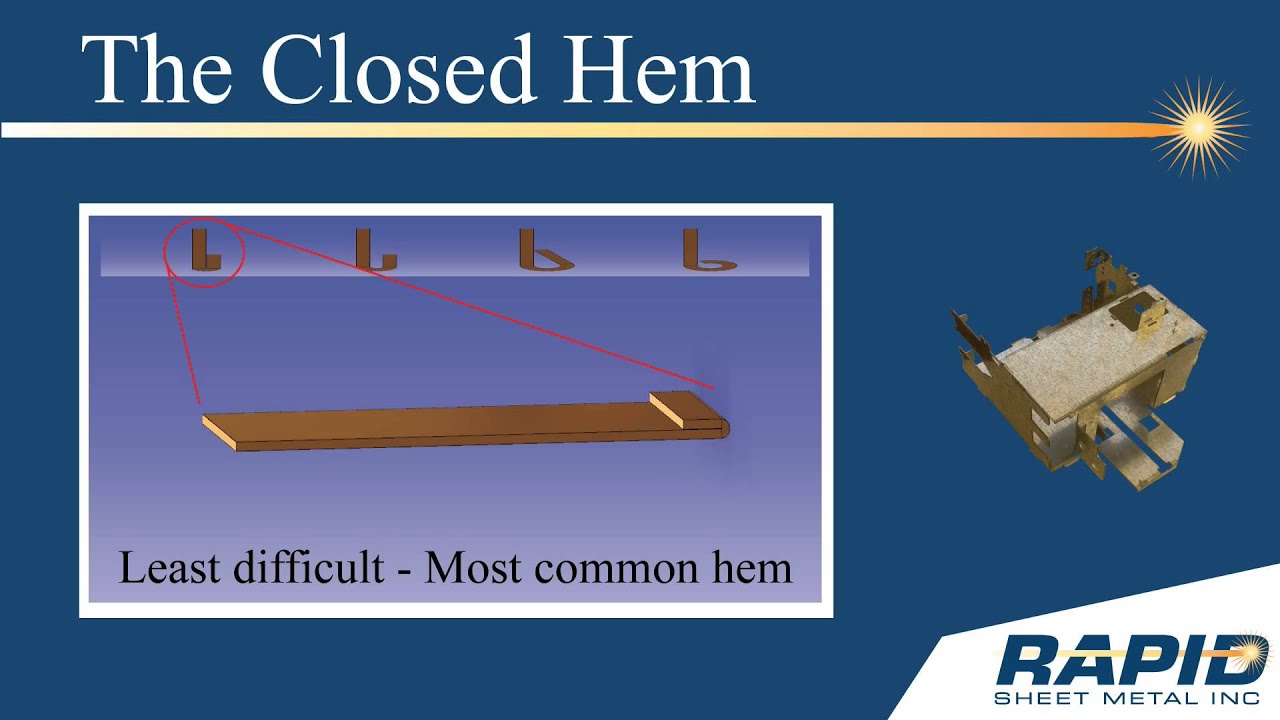

Create a bend with acute angle tooling in the metal 30 is preferable but 45 will work for some circumstances.

Hemming is used widely in sheet metal operations.

During this process the edge of sheet metal is folded over.

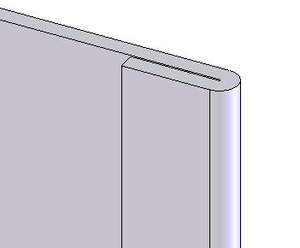

A hem is a flange that has been bent more than 180 degrees.

Sheet metal is available in a variety of gauges.

Seams are commonly used in the food industry on canned goods on amusement park cars in metal roofing and in the automotive industry.

Hemming is a metalworking process that involves rolling the edge of sheet metal over and onto itself essentially creating an area of two layers.

Hems are commonly used to reinforce an edge hide burrs and rough edges and improve appearance.

When working with a brake press hems are always created in a two step process.

In sheet metal hemming means to fold the metal back on itself.

Automotive body panels and automotive parts such as deck lids trunk lids doors hoods and tailgates are formed by hemming process.

Four types of hems are the flattened hem open hem teardrop hem and rope hem seefigure 1.

They also increase the part s edge stiffness and improve the edges dimensional accuracy.