In ox worldwide we have stock of the semi manufactured products that make up the eco beams with which it is quick to assemble the lifting beam required by the customer within the range of capacities from 1 to 10 tons and lengths from 1 to 4 m.

H lifting beam.

In addition it is also widely used in ships bridges lifting and transportation machinery brackets equipment foundations foundation piles etc.

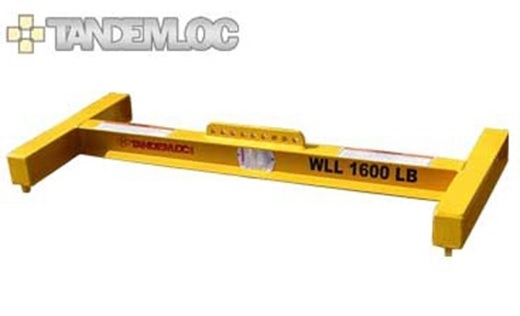

Container lifting beams designed for lifting soft side bulk container or other types of flexible containers with lifting loops webbing.

Crosby ipvuz beam lifting clamps crosby ipvuz beam lifting clamps crosby ipvz beam lifting clamps crosby ipvz beam lifting clamps i or h beams.

Parts with critical width length ratio or that require multiple safeguards due to structural peculiarities can be gripped easily and moved with a high degree of shape.

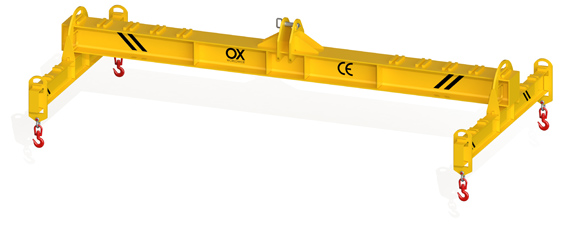

The h lifting beams offer more stabilization and distribution of the loads along the object.

As well h lifting beams work really well with loads that have a extreme lenght width ratio.

I beam steel the ultimate difference analysis h beam weight i beam weight.

As for the difference between h beam and i beam you can refer to the article below.

815 229 5667 toll free.

View our wide selection of lifting and spreader beams.

H lifting beams for example are perfect for the lift of an industrial basket in siderurgical.

We make fixed length and adjustable lifting beams for numerous applications glass panel lifting beams plate lifting beams low headroom lifting beams roll lifting beams and even non conductive lifting beams.

The frame of the eco beam consists of one structure with a pattern of holes a central.

The eco beam is an economical and fast delivery lifting beam.

Crosby ipbc horizontal lifting clamps crosby ipbc horizontal lifting clamps crosby ipstartec11 beam lifting clamps crosby ipstartec11 beam lifting clamps structural bridge beams.

H beam vs.

This is the perfect lifting frame for when your four points of lift will vary but you would prefer one system to cover all your lifting needs.

Economy h beam low headroom adjustable economy coil lifters telescoping beams adjustable bale lifting beam basket lifting beam bulk container lifting beam small length fixed beams ultra low headroom spreader beams and pallet lifters.

Machining welding manufactures quality lifting beams made in cokato mn usa.

Built in lugs on each beam keep the loops or webbing of the container from sliding off or inward and unbalancing the container.

The h shaped beam configuration features a oversized lifting eye for fast connections.

We pride ourselves in the quality of our welds and our finishing techniques.